Understanding the Manufacturing Process of PVC Plastic Boards

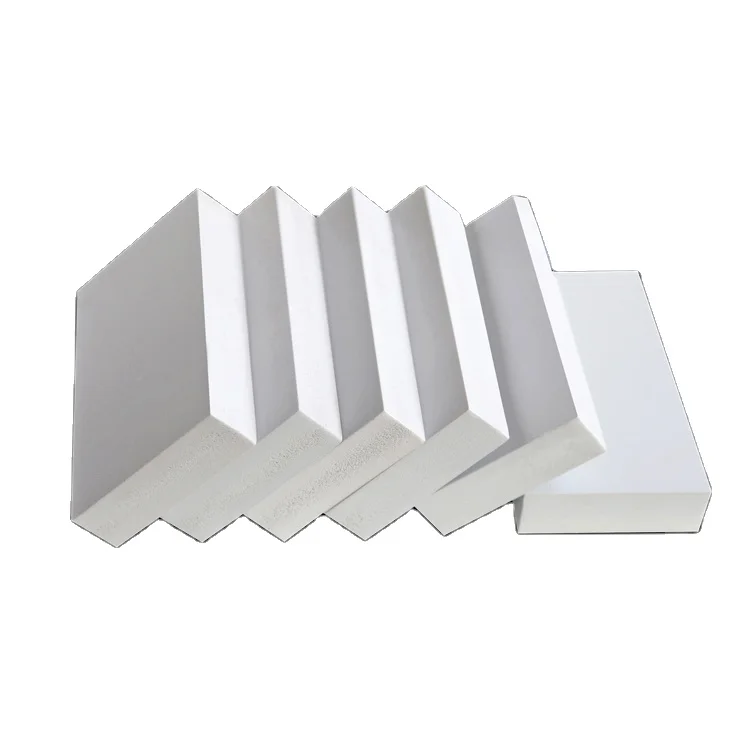

PVC plastic boards are now commonly used among several industries because of their strength, flexibility and low maintenance requirements. These kinds of panels are widely used in the construction industry, interior design and signage. This paper, will go deeper in the Complex processes for making PVC plastic boards discussing its Scientists concepts behind of pvc plastic extrusion and technics to improve productivity during production process as well common problems, also alongside presented inventions that rethinking it way.

How to Manufacture PVC Plastic BoardStep by Step Guide

The first stage of PVC plastic sheet production is to mix the raw materials including: - PVC resin and plastisizers(stabilisers, impact modifiers) These additives have an important influence on the performance of pvc panel sheet board, MCU flexibility and firmness impact resistance.

After its ingredients are mixed, the material is heated, melted and shaped by extrusion. An extruder heats and melts the PVC resin, then forces it through a die that shapes liquid plastic composite into an objectified profile thereby becoming fixed. Afterward, the profile is chilled and slited for delivery.

Science Of PVC Plastic Extrusion

A primary method in the PVC business is plastic extrusion, which includes forcing molten PVC through a die to create it into formed work. This is necessary for the creation of PVC plastic boards as it allows to shape and size this material very accurately.

With the extruder machine, which consists of a rotating screw in the barrel that forces molten PVC through die and most each time functions in this process. Based on the customer requirement, a die (steel form) is prepared to give desired profile by shaping of PVC.

Efficiency in PVC plastic board production

The extrusion process must be tightly controlled to ensure minimal energy waste during the production of pvc plastic sheets board. This includes monitoring temperature setting, pressure and flow rate in each equipment step.

Efficiency can be affected through many factors, such as feeding speed into the extruder, board thickness being made and cooling time for material to solidify.

Challenges and Solutions During PVC Plastic Board Manufacturing

In the producing process of PVC plastic board, surface defects, including warping edge and that faded or cracked on sun exposure have been always causing a great deal of problems. Defects can be due to uneven cooling rates, poor materials quality or bad die design and lack of maintenance on machines.

Solving these problems demands regular surveillance of the extrusion process and conducting required modifications. This could entail tweaking the business end via die design, or changing temperature and pressure settings, or even finding a way to use some high-end materials.

Turnkey Solution for the Production of PVC Plastic Board with Innovative Technologies

Innovative technologies are changing the face of PVC plastic board production in recent years. 3D printing, for example, can be used to print custom PVC board shapes and patterns which are more precise and less waste than ever before.

The nano drug in the treatment of pvc board foam board production is added to another technology driving increases These additives are aimed at improving the strength, durability and weather resistance of PVC boards making them a better long lasting products.

Conclusion

PVC plastic boards are being a versatile and durable material that is specially used in several industries. Consistent quality and production efficiency are only achievable with a full understanding of the manufacturing process. If manufacturers maintain careful control over the extrusion process, deal with common obstacles directly and introduce fresh developments to their technologies, then they will consistently improve the quality of PVC plastic boards.

Recommended Products

Hot News

-

PLUSWIN Spring Festival Vacation Notice

2026-02-09

-

Fewer Layers, Greater Intelligence: How 3-Layer PVC Co-Extruded Boards Deliver Superior Performance

2025-12-11

-

'PLUSWIN' made a brilliant appearance at the 136th Canton Fair, with innovative products leading the industry's new trend

2024-10-23

-

frequently asked question (FAQ)

2023-11-30

-

PVC foam board Vs KT BOARD: Which Is better For Your Sign?

2023-11-27

-

Understanding the Versatility of PVC Foam Boards

2024-07-12

-

Foam PVC board vs Solid PVC board: Which Is Better?

2024-06-12

-

PVC FOAM BOARD APPLICATION

2023-11-27

-

The New Elegance of Lacquered Fans - PVC Foam board Surfaces, Leading the Global Trend!

2024-06-26

-

"Jiaying" won the title of Alibaba International Station's Most Powerful Marketing Merchant of the Year

2024-06-26