Fewer Layers, Greater Intelligence: How 3-Layer PVC Co-Extruded Boards Deliver Superior Performance

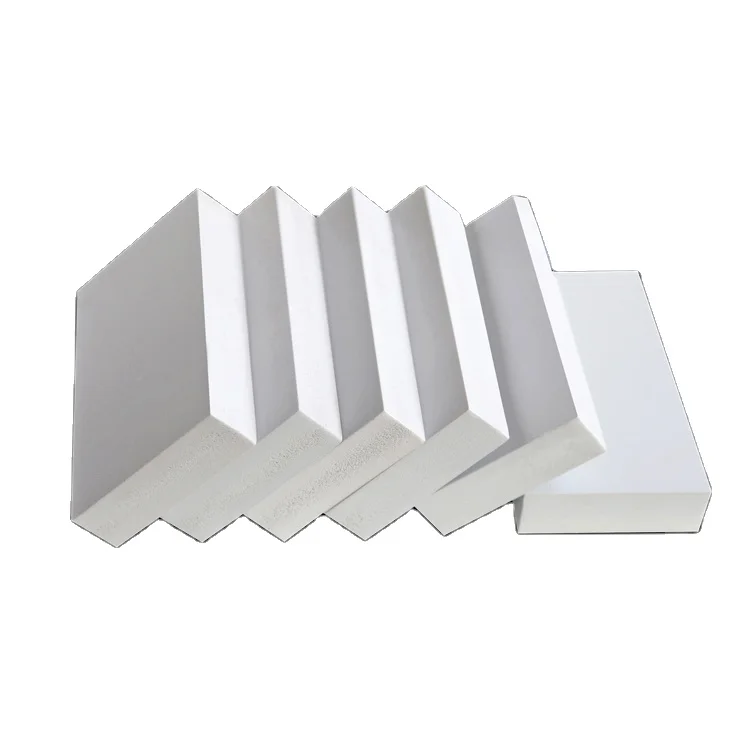

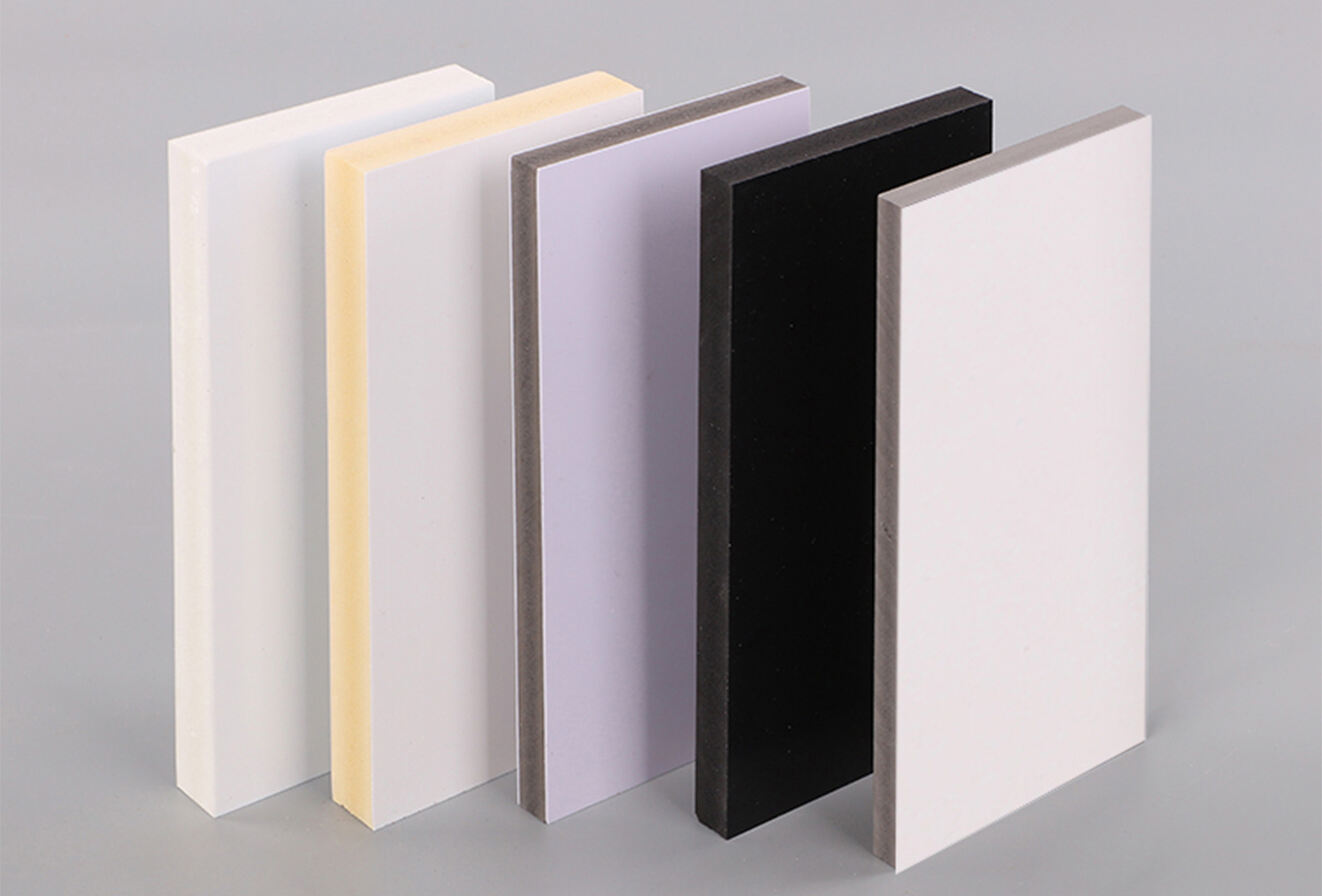

In the modern construction and decorative materials industry, PVC co-extruded board has become a popular choice for applications such as wall cladding, interior decoration, and furniture components, thanks to its excellent waterproofing, moisture resistance, corrosion resistance, and eco-friendly properties. However, as the market evolves, a new product claiming to enhance core density and screw-holding power through a "5-layer co-extrusion" process has emerged. As seasoned experts in the field, we remain committed to a science and performance-driven approach. Today, we delve into the core technology of PVC co-extrusion boards and explain why, at this stage, the mature and reliable 3-layer PVC co-extruded board remains the optimal solution for balancing performance and cost-effectiveness.

1. Core Technology and Advantages of PVC Co-Extruded Boards

A PVC co-extrusion board is produced by simultaneously extruding and fusing PVC materials with different formulations or colors through a shared die head using two or more extruders, forming a multi-layer composite structure in a single step. The core advantages of this process are:

- Monolithic Structural Integrity: All layers bond tightly in a molten state without any adhesive, eliminating risks of delamination and ensuring long-term structural stability.

-

Clear Functional Layering: A typical three-layer structure is designed as follows:

- Top Layer: High-quality, weather-resistant, UV-stabilized, and scratch-resistant PVC for lasting protection and an aesthetic finish.

- Core Layer (Middle): Provides primary structural support; its key performance depends on the formulation's mechanical strength.

-

Bottom Layer: Balances the structure and may offer additional functional or decorative properties.

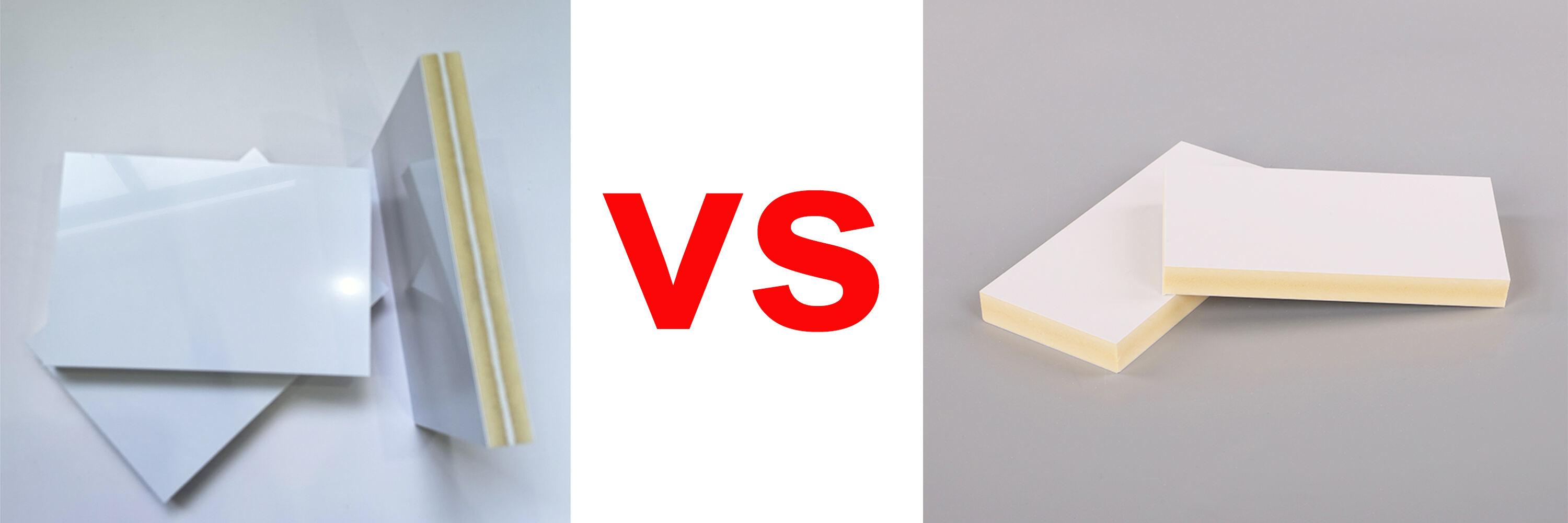

2. Claims and Current Limitations of "5-Layer PVC Co-Extruded Boards"

The newly marketed "5-layer PVC co-extruded board" aims to increase core density by adding more layers within the central region, intending to enhance screw-holding power.

However, it is essential to objectively note that transitioning a concept into a stable, mass-producible technology requires profound expertise and extensive validation. Currently, the 5-layer co-extrusion process still faces significant challenges in the industry:

- Dramatically Increased Process Complexity: Each additional co-extrusion layer exponentially raises demands on extrusion equipment precision, die design, and control over melt flow and temperature, often leading to uneven layer fusion and stress concentration.

- Performance Uncertainty: A more complex structure does not guarantee superior core performance. Without a thoroughly validated formulation, simply adding layers may compromise other critical properties, such as overall toughness, impact resistance, and long-term thermal stability.

- Cost-to-Benefit Ratio: The complex process results in higher energy consumption, lower yield rates, and increased overall costs, which are ultimately passed on to consumers without a commensurate performance guarantee.

3. Our Commitment: High-Performance 3-Layer PVC Co-Extruded Boards, Proven by Comprehensive Testing

We firmly believe that core material performance stems from scientific formulation and mature processing, not merely from stacking layers. Our 3-layer PVC co-extrusion technology, refined over decades of optimization, represents a mature and reliable solution. Through a rigorous raw material selection and formulation system, we ensure outstanding performance from the surface to the core:

- Addressing the Misconception of a "Soft Core and Weak Screw-Holding Power": This is typically an issue of formulation and process, not an inherent flaw of the 3-layer structure. Our core layer employs a high-density, high-fill, specially modified formula combined with precise plastification and extrusion, resulting in exceptional compactness and cohesive strength.

- Comparative Test Data from Authoritative Labs: We commissioned third-party testing to compare our premium 3-layer PVC foam board with market alternatives (including some 5-layer samples). The results are clear:

(1)Screw-Holding Power Tests: Our 3-layer board fully meets or exceeds the highest national standards and industry requirements for key indicators such as axial pull-out force and lateral load resistance, performing on par with or better than claimed 5-layer PVC boards.

(2)Overall Strength Tests: In assessments of flexural strength, impact resistance, and creep resistance—which reflect the board's structural integrity—our monolithic 3-layer structure demonstrates superior stability and durability due to more uniform internal stress distribution.

(3)Long-Term Stability: After accelerated aging and thermal cycling tests, our 3-layer board showed no delamination or performance degradation, validating the reliability conferred by mature processing.

4. The Informed Choice: Mature, Reliable, and Cost-Effective 3-Layer PVC Co-Extruded Boards

For the vast majority of applications—from exterior wall panels and terrace ceilings to interior kitchen/bathroom decor and furniture substrates—a scientifically formulated, maturely processed, and quality-assured 3-layer PVC co-extruded board offers more than sufficient performance. It avoids the extra cost associated with unnecessary and unproven complex processes, ensuring controllable project expenses and long-term material reliability.

We are not opposed to innovation; we advocate for value-based, rational decision-making. In the pursuit of better screw-holding power, we choose to deepen our expertise in core formulation—the fundamental approach—rather than adopting an underdeveloped complex structure. This reflects our responsible commitment to customers: providing a time-tested, high-performance, and cost-effective solution.

Choosing our 3-layer PVC co-extruded board means selecting not just a material, but a reliable promise backed by technical confidence. Let's work together to build stronger, more enduring spaces with smarter, more mature material technology.

Recommended Products

Hot News

-

Fewer Layers, Greater Intelligence: How 3-Layer PVC Co-Extruded Boards Deliver Superior Performance

2025-12-11

-

'PLUSWIN' made a brilliant appearance at the 136th Canton Fair, with innovative products leading the industry's new trend

2024-10-23

-

frequently asked question (FAQ)

2023-11-30

-

PVC foam board Vs KT BOARD: Which Is better For Your Sign?

2023-11-27

-

Understanding the Versatility of PVC Foam Boards

2024-07-12

-

Foam PVC board vs Solid PVC board: Which Is Better?

2024-06-12

-

PVC FOAM BOARD APPLICATION

2023-11-27

-

The New Elegance of Lacquered Fans - PVC Foam board Surfaces, Leading the Global Trend!

2024-06-26

-

"Jiaying" won the title of Alibaba International Station's Most Powerful Marketing Merchant of the Year

2024-06-26

-

HANGZHOU JIAYING TRADE CO.LTD, specializing in the production of PVC board with its excellent quality

2023-11-27