Klasifikimi i pllakës së pambukut PVC

Tavolina e pambukut PVC (e njohur gjithashtu me emra të zakonshëm si tavolinë pambuku, tavolinë andy) është një tavolinë shumë praktike dhe lehtë. Dimensionet e klasifikimit të saj janë shumë të shumta, kryesisht në procesin e prodhimit, strukturën e porozitetit dhe përdorimin funksional. Për t'ju bërë më të qartë, PLUSWIN ka organizuar mënyrat kryesore të klasifikimit më poshtë për ju

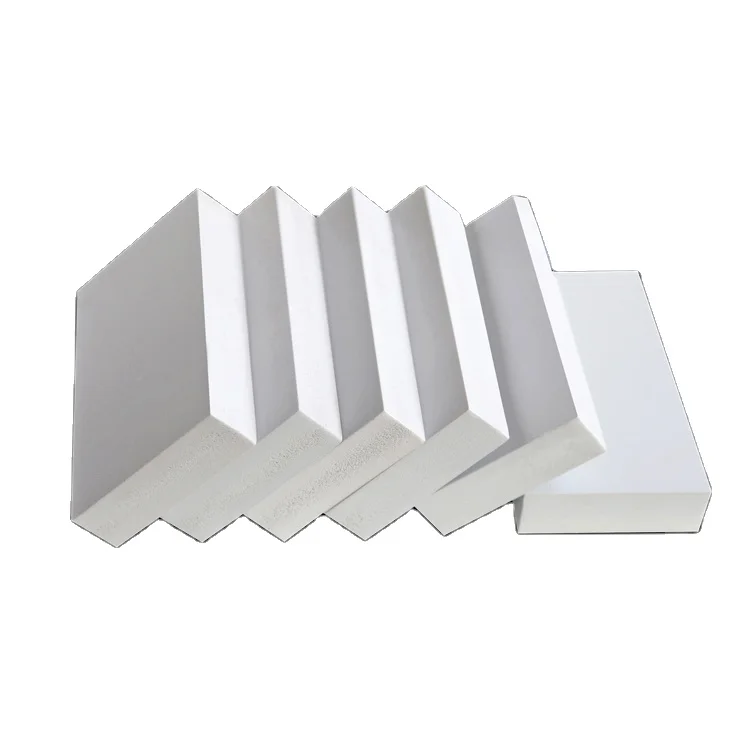

1. Klasifikimi sipas procesit të prodhimit dhe strukturës së gomëzimit (klasifikimi më i zakonshëm) Kjo është standardi bazë për dallimin e pllakave të pluhurit PVC i cili përcakton drejtpërdrejtëteksturën e sipërfaqes dhe vetitë fizike të pllakës. · Pllaka me Gomëzim të Lirë · Emra të tjerë: Pllakë e zakonshme gomëzie, pllakë Sintra. · Karakteristikat Masës i shkrirë zgjerohet lirisht pas daljes nga kasti, pa një shtresë të dendur të fortë në sipërfaqe, duke paraqitur një teksturë të hollë "të papunuar" ose të palëmuar. Ndihet e butë në prekje, ka dendësi të ulët dhe është relativisht e lirë. · Zbatimi: I përshtatshëm për skenarë me kërkesa të ulëta për gjithçka që lidhet me imthësinë e sipërfaqes, si për shembull tabela reklamuese, tabela për kornizim figurash, gdhendje, printim, mbulesa paketime etj.

·Celuka Foamed Board ·Alias: Celuka board. ·Karakteristikat: Përmes kontrollit të veçantë të formës, sipërfaqja e tavolinës ftohet shpejt për të formuar një shtresë të dendur "tek pelli". Kjo e bën sipërfaqen e tavolinës shumë të rrjedhshme, të fortë, rezistente ndaj konsumit, jo të lehtë për të pasur gërvishtje, dhe vetitë mekanike janë më të mira se tavolinat me shkumim të lirë. ·Aplikimi: Përdoret gjerësisht në fusha të larta si tabela të mobilieve (çelësa, kabineta për banjo), ndërtesa me mure të jashtëm dhe panele dekorimi interiore. ·Tavolina e Shkumosur me Ko-Ekstrudim ·Karakteristikat: Shtresa të ndryshme materiale me funksione të ndryshme (si shtresa me rezistencë të lartë ndaj motit, shtresa dekorative) kombinohen së bashku përmes teknologjisë së ko-ekstrudimit. ·Aplikimi: Mund të arrijë ngjyra të veçanta, tekstura ose funksione të përbëra (si anti zjarri, anti-ultraviolet), dhe përdoret shpesh në muret e jashtëm të ndërtesave dhe në dekorimin e brendshëm të lartë.

2. Klasifikimi sipas Strukturës së Qelizave dhe Vetive Fizike · Panel me xham i me qeliza të hapura kundrejt Panelit me xham i me qeliza të mbyllura Panel me qeliza të hapura: Buzonjat e brendshëm janë të lidhur mes vete ose pjesërisht të lidhur, gjë që siguron absorbim më të mirë të zërit. · Panel me qeliza të mbyllura: Buzonjat nuk janë të lidhur me njëri-tjetrin, çka ofron rezistencë më të mirë ndaj ujit dhe lagështisë, si dhe izolim superior dhe ruajtje nxehtësie. · Panel me xham i butë kundrejt Paneli me xham i ngurtë · I butë: Përmban plastifikues, ka shkallë zgjerimi të madhe dhe është i butë në teksturë, shpesh përdoret si material izolues. · I ngurtë: Përmban pak ose aspak plastifikues, ka forcë, shkallë zgjerimi të vogël dhe përdoret kryesisht si material struktural ose material dekorativ në ndërtim. · Panel me xham me zgjerim të ulët kundrejt Paneli me xham me zgjerim të lartë · Bazuar në shkallë të ndryshme zgjerimi, mund të ndahet në me zgjerim të ulët (<15 herë) dhe me zgjerim të lartë (>20 herë). Sa më e madhe të jetë shkalla e zgjerimit, aq më i lehtë është paneli dhe aq më i mirë efekti i izolimit dhe izolimit nga zhurma, por forca do të zvogëlohet relativisht.

3. Klasifikimi sipas funksionit dhe qëllimit Për të përshtatur me kërkesat specifike mjedisore, pllakat e ngrirë PVC mund të ndahen edhe më tej si më poshtë: · Pllaka me efekt ngadalësues zjarri: Me shtimin e agjentëve ngadalësues zjarri, plotëson standardet e mbrojtjes nga zjarri në ndërtesa (si p.sh. klasa B1) dhe është e përshtatshme për hapësira publike si spitalet, metrot, dhe qendrat tregtare. · Pllaka rezistente ndaj rrezeve UV: Me shtimin e aditivëve rezistent ndaj rrezeve të diellit, ka rezistencë të lartë ndaj kushteve atmosferike dhe nuk zhduket lehtë, përdoret veçanërisht për tabela reklamuese jashtë shtëpisë ose dekorim të fasadave. · Pllaka miqësore me ambientin: Duke përdorur aditivë miqësorë me ambientin, plotëson standardet e Bashkimit Evropian RoHS, ACH dhe të tjerë, përdoret për mobilje fëmijësh ose produkte eksporti. · Pllaka me shtresë/aluminizuar: Me një shtresë sipërfaqësore prej filmi PVC, PET ose folje alumini, rrit dekorativitetin dhe rezistencën ndaj konsumit, përdoret shpesh për derë kabineti të kompletuara, etj.

Krahasim i përmbledhur Nëse po bëni fjalë reklamuese ose gravura të thjeshta, tabla me xham me çlirim të lirë ka efikasitetin më të lartë të kostos; nëse po bëni kabinete ose keni nevojë të bartni mobilje të rënda, tabla me xham me formim të shtresës është zgjedhja më e mirë

Produkte të rekomanduara

Lajme të nxehta

-

Më Pak Shtresa, Inteligjencë Më e Madhe: Si Kombinatet 3-Shtresëshe PVC me Ko-Ekstrudim Ofrojnë Performancë Superiore

2025-12-11

-

'PLUSWIN' bëri një paralajmërime brillante në Fairin e 136-të të Kantonit, me produkte inovative që lidhen trendin e ri të industrisë

2024-10-23

-

pyetje të rregullta (FAQ)

2023-11-30

-

Larg PVC foam board Vs KT BOARD: Cila është e mira për shenjën tuaj?

2023-11-27

-

Kuptimi i shumëfishtësisë së bordeve të larg PVC

2024-07-12

-

Panel me Foam PVC vs Panel me PVC Solid: Cila është e Larg dhe Larg?

2024-06-12

-

APLIKIMI I PANELIT ME FOAM PVC

2023-11-27

-

Eleganca e Re e Ventilatorëve me Lack - Siperfaqe me Panel PVC me Foam, Duke Larg dhe Larg Trendin Ballkanik!

2024-06-26

-

"Jiaying" u marr titullin për Larg dhe Larg Më Të Forçuar i Vjetit në Alibaba International Station

2024-06-26

-

HANGZHOU JIAYING TRADE CO.LTD, e specializuar në prodhimin e bortit të PVC-it me kualitet të mirë

2023-11-27