Need something that is durable and can be used indoors as well as outdoors? One of the most beautiful wood plastic panel board you can try that resists moisture, insects and decay is WPC. In this information piece, we are going to take you through the advantages of WPC panel board and production process behind one very innovative committee as well how it helps in various applications.

If there is one thing that distinguishes the WPC panel board, it is its remarkably high durability and resistance. Once applied, this makes it well-suited for areas that receive a significant amount of traffic e.g. decks, patios and walkways. On top of that, its all-weather durability (including in rain and snow) makes it a great choice for year-round outdoor use.

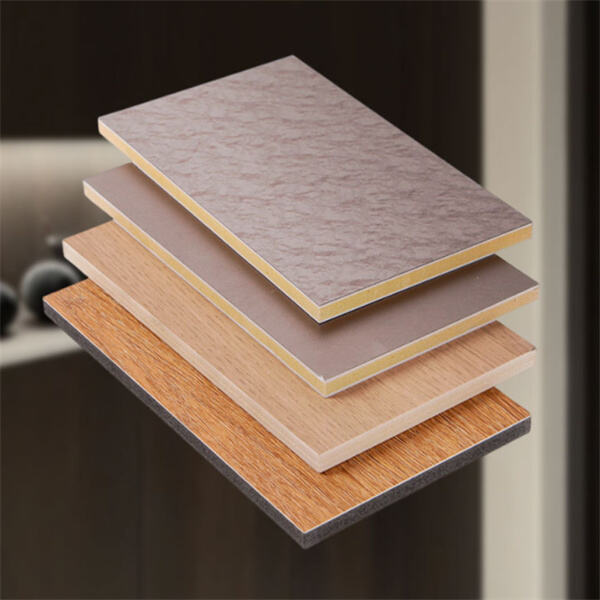

The solid material of the WPC panel board and related piece makes have this unique component to them that guarantees these planks stay forever better than its counterparts. Manufacturers have found a way to fuse wood and plastic together, giving you the unique balance of each. The wood is responsible for the natural durability and aesthetics, while to plastic improves rigidity, strength but also resistance against moisture. WPC panel board is much more durable than traditional wood and its maintenance is almost inexistent, making overall costs lower in the long term.

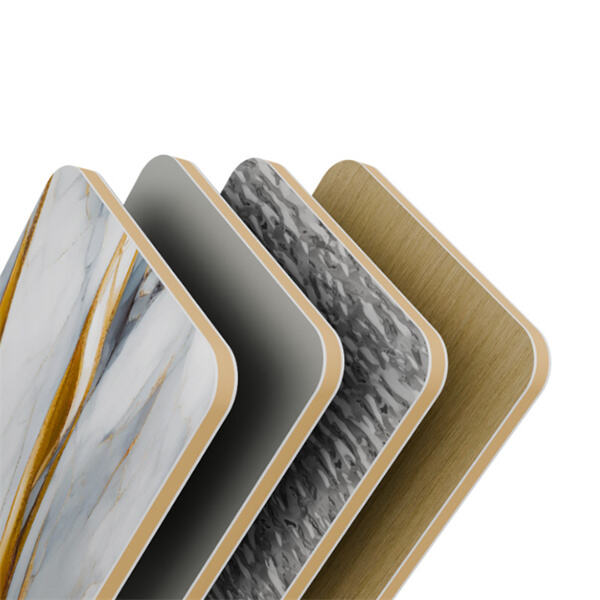

The WPC panel board is more fire-resistant than traditional wood materials and also has strong resistance to rot, decay and insects so it will not cause you tedious infestation worries (such as termites) or bacteria that can threaten your health. It also features slip-resistant surface, making it extremely safe for families with kids and elderly. Due to its versatility, WPC is used in a variety of indoor and outdoor applications such as flooring, decking, fencing, wall cladding... with the following customized colors or textures without designs to address individual preferences.

Using WPC panel board is easy, it can be cut and shaped to shape. It is easy to maintain by cleaning with soap and water so that the watch continues to show off its style. For applications such as decking or flooring, it is important that the surface be properly installed in order to optimize its durability and safety.

What is the quality and service of WPC panel board

However, one must not forget that every WPC panel provides a different quality than the other. Choosing a reliable quality manufacturer & supplier who provide high-quality materials and strict adherence to process control is important. Select a business that provides good customer service and support to answer any questions or bring interest in the shortest time.

Last year, our company is devoted to exporting and selling PVC panels. We offer solutions for trading Wpc panel board board throughout a quantity of industries. We offer, sell which make it possible to advertise building which is different.

If you'd like to purchase in the case that you need to customize size and color based on the specifications, we possess the ability to Wpc panel board your logo films, packaging style and marketing materials based on the requirements of your from us, or.

Wpc panel board foam boards are manufactured employing a formula that is high-quality which includes an area that is difficult smooth surfaces with no color differences, uniform foaming, without having any voids and contains multiple ROHS/SGS/REACH certifications.

Communicate Wpc panel board methods plus logistics based on industry needs of the customers. Transparently video or feedback(photo) within the production towards the customers, package, weight, surface, hardness test feedback to your customers