Knowing the steps of PVC foam board manufacture

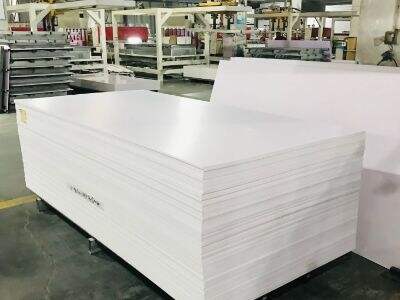

PVC foam board is a lightweight, weather-resistant-telephone material that has been used by many industries as well as many more applications for it. The production of PVC foam board requires a few key steps that guarantee the quality and uniformity of the board.

The production process of PVC foam board, the first step is to mix the raw materials. The PVC resin, plasticizer, foaming agent and other additives are precisely weighed and mixed uniformly in a high-speed mixer. The blend is heated and melted to give a uniform melt.

The finished compound is then fed into an extruder in which the compound is heated and pushed through a die to attain the desired shape and thickness of the PVC foam board. The board is subsequently cooled and cut into the desired shapes then further treated with subsequent process steps like embossing or printing.

Integration of production process of pvc foam board

Effective production process is the key to making PVC foam board with high quality on time. Through the efficient manufacture, Jiaying can save the production costs,reduce the waste and enhance the efficiency of production.

In order to improve the production efficiency in the process of PVC foam board, Jiaying also took into consideration the equipment layout, operation standard and quality control point deployed on the key process in the process of the PVC foam board production.

With an orderly and reasonable layout of iron and steel production floor, Jiaying would reduce material handling and handling time and cost. Having procedures as a standard for existing processes makes sure everyone takes the same approach and does it the correct way – less error chance and misunderstanding of how things are done.

The following is PVC foam board material process processing details as this video showing.

The manufacturing process of PVC foam board can be divided into many process, which in order to have better product quality and one of the most important factors is the production process and equipment. Knowing these key steps, she might be able to streamline the process, thus ensuring more consistency in production.

Extrusion is one of the essential steps in the PVC foam board material. During extrusion, the material is hot and forced through a die to make a desired shape and thickness of the board. This is so important to obtain even density, and board thickness.

Cooling and cutting is another essential process for pvc foam board material. After extrusion, the board is cooled with water or air and is then cut to length. This helps shrink the board and makes sure it meets the dimensions here that Jiaying has specified.

Improving efficiency of production line of PVC Foam board

The market is fiercely competitive and efficiency is the key for Jiaying to be competitive and to satisfy growth pvc foam board demand. Through its manufacturing process, Jiaying can improve productivity, saving in production, better product quality, and a satisfied customer.

The investment of advanced devices and technology is also helpful in improving the production efficiency of PVC foam board in production process. Some of the work is being freed up by automation and computerized systems Jiaying can employ to speed up production, cut costs on labor and decrease the chances of human error.

Compound feed In addition, effectiveness can be maximised by optimizing the use of raw materials. By monitoring and managing the raw material inventory closely, Jiaying is able to minimize waste, reduce downtime and guarantee the availability of material for production.

Quality control in production of PVC foam board

Quality control is a key point in pvc foam board making. By controlling quality from the mill, Jiaying can be assured that each board meets the demands of strength, toughness and appearance.

One of the primary quality controls is frequent testing of the raw materials. With the testing on PVC resin, plasticizer, foaming agent etc. raw material & additives, Jiaying is able to check the quality and performance of the material to make sure every ingredient is stable and good for production.

Monitoring during the production process is another crucial form of quality control. Jiaying monitors her equipment, such as looking at temperature and pressure settings, and even checks the final product, amongst other things, to be able to address any problems that may arise and which could potentially have an effect on the quality of the PVC foam board.