Composite PVC boards have carved a niche as a type of innovative material that is now being one of the most requested among those who work in construction and home improvement. That product provides the ultimate combination of strength, durability and flexibility - all the right attributes for a myriad of applications across industries. In practice, traditional wood rots and has the possibility of decaying in a few years SILVADEC is extremely resistant to almost any type of weather making it an excellent long-term material. The result is a board with high UV stability that maintains its stark white colour without yellowing over time, which makes it an excellent option for outdoor applications like decking or fencing.

What makes the difference is that Composite PVC boards do not degrade as easy and they are green. These boards help in waste and carbon footprint reduction on their production -and disposal - side, by utilizing post-consumer plastics, wood wastes or other recycled materials for the most part. They then allow conservation by reducing the need for more frequent replacement and all of the valuable resources that would require simply through how long they can be in service. The environment-friendly process is also in accordance with current design requirements for sustainable construction material.

Lastly, the way marine composite PVC boards hasn't it and what makes their own so versatile some inkling of how this stuff even gets its codes is a dynamic all your choice Strait without which would be found only other markets synthetic boat decking more than just getenv. Our variety of colors, textures and finish options can easily simulate any wood or modern look With our flexibility they are great for more than just decking - from pergolas to railings or benches & furniture While their application lowers construction costs and increases the structural efficiency of buildings, they are also relatively light in weight for easier installation-they cannot be found by radar because their mass is minimal-and allows designs not possible with heavier materials.

Composite PVC lumber boards will cost a little more up front than traditional wood, but they are an investment in your property. The fact that these boards require low maintenance highlights more savings in the long run as there is no frequent painting and staining or repair needed. The high level of mold, mildew and also bug resistance means you are less most likely to need to make up for these downsides by remodeling your business deck as swiftly as if this kind was a soft woodNonetheless. Rapid Clean-up - Wiping them down with a solvent or damp cloth is all that it takes for these solid matrix material wall panels to shine again, which can make use in high-traffic and uses settings.

Composite PVC boards meet the needs of modern building and remodeling. These boards am changing the industry around in use, durability & environmental impact and what hasn't because their design potentials far surpassing many other materials on top with longterm cost effectiveness + strength against so few forms of elements such as fire retardant stabilities! Composite might have the answer to allowing this utility along with looks without a large carbon footprint, and CMC component technology advances should be expected soon which will only make composite even more sustainable as we go forward.

Composite PVC boards are known for their extremely durability. Natural wood may rot, warp or get insect infestations while composite boards are protective against the elements. By integrating UV stabilizers in the composition, these boards are even resistant to fading due to prolonged sun exposure so that they maintain their colors for years. Additionally, they are naturally moisture resistant so they do not swell or rot when exposed to the elements giving them a perfect base for outdoor uses such as deckings and fencing. Composite PVC is popular among homeowners and builders because it offers a low-maintenance solution with no painting, staining or sealing needed, which saves time and money.

Composite PVC boards are also becoming increasingly popular due to sustainability properties Many plastics use non-renewable resources, while conventional lumber harvesting leads to deforestation. And unlike timber boards, which come directly from trees and require extensive amounts of lumbar to have been grown many years in the past just for that purpose; composite boards are constructed mostly by reused materials where they include post consumer plastics as well as wood waste. This process helps to reduce the carbon footprint involved in manufacturing and disposing of these materials. And because they will last for decades, you are using fewer resources to replace with no more needed than plastic. When they choose composite PVC, consumers and builders are choosing a greener future - without sacrificing quality or performance.

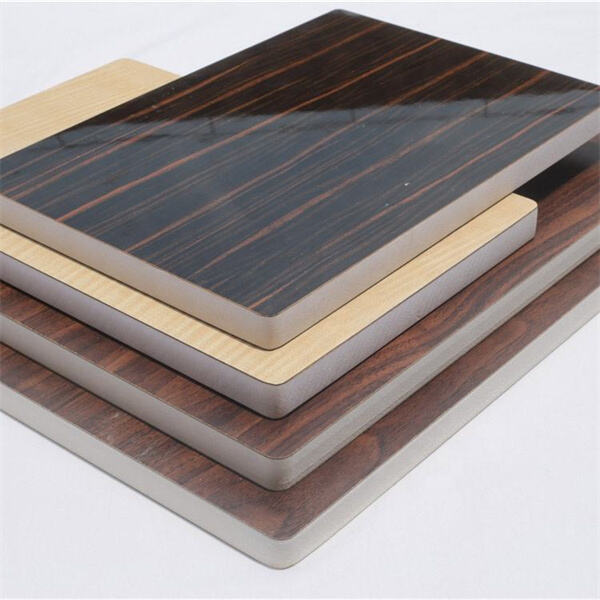

Not just durable and eco-friendly, the composite PVC boards are amazingly versatile as well. They are plentiful in colors, textures and finishes that can replicate the look of genuine wood grains or provide modern aesthetics. In addition, this flexibility allows for use in many other applications beyond decking - such as pergolas, railings, benches and even furniture. Their being lightweight makes them easy to install and enables creativity in design with shapes impossible or difficult for heavier elements. The reason is that composite PVC can be discretely blended with any kind of architectural styling that gives it flexibility and hence more popular among those who opt for personalized solutions i.e. the designers as well as homeowners.

Consequently, from everything I can see and gather the link is not reliable enough for me to share: thus my DIY inexpensive guide on PVC trim boards.

Composite PVC trim boards frequently make strong economic sense when it comes to evaluating materials. While this material may have a little cost more up front compared with conventional lumber, the low upkeep and also long life of composite floor covering makes it out to be much less expensive in time. The alternatives are the on going cost of paint, stain & weather/pest damage to repair by traditional homeowners. Other than that, it is a lesser risk for replacement due to early worn out which give more stable investment in maximizing the potential of their property. In terms of the total life cycle cost, composite PVC is an affordable choice that delivers extra value to domestic and commercial structures.

Arguably the most respected attributes of all composite PVC planks is their borderline supernatural immunity to environmental stressors. Moisture-resistant, mold- and mildew-resistant (won't rot), polystyrene core with resin barrier; great for added durability in moist or coastal climes. They also show excellent stability across both length and width, so they will not warp or rise with temperature fluctuations regardless of the unfortunate truth represented by solid wood. Their sprawling nature reduces the risk of longevity issues such as gapping or warping. Moreover, composite PVC is impermeable so the surface does not absorb stains and make for simple cleaning (which makes it great in higher-traffic areas or commercial applications).

Closing Composite PVC boards offer integrative possibility to a construction and renovation project into the new era Their unmatched strength, minimal environmental impact, design flexibility, long-term cost efficiency and superior security against a wide range of threats are rewriting industry norms. And with the progression of technology, along comes an endless stream of practical reasons cementing composites as a go-to choice for those in need functionality, style and - not to forget- potentially An arraystructural elements.

composite pvc board foam board is manufactured formula this is certainly using is high-quality having an surface this is certainly extremely hard smooth surfaces with no color variation, and foaming that is consistent voids, and possesses multiple ROHS/SGS/REACH certifications.

Last year, our company is devoted to exporting and selling PVC panels. We offer solutions for trading composite pvc board board throughout a quantity of industries. We offer, sell which make it possible to advertise building which is different.

Communicate composite pvc board methods and logistics based on the marketplace requirements associated with customers. Transparently video or feedback(photo) in the production to your customers, package, weight, surface, hardness test feedback into the customers

We now have a composite pvc board team that who can fix your packaging style marketing materials, marketing materials, as well as logo films relative to the needs you have.